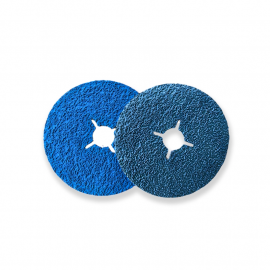

Fibre abrasive discs VSM : Performance and Sustainability for All Your Meulage Works

The fibre abrasive discs VSM are specially designed to meet the requirements of professionals working on hard metals, non-ferrous materials or complex alloys. Available in different compositions such as ceramics zirconium and alternatives to high performance, these discs allow to perform grinding, deburring, and finishing work with maximum precision while ensuring exceptional longevity. Their advanced technology and robust structure make it the ideal tool for optimized performance in industrial environments.

Types of Abrasive Discs Fibre VSM

-

Abrasive Discs Ceramic XF870 VSM

- Rapid material removal: Ideal for demanding medium-pressure grinding.

- Self-sharpening ceramic seeds: These discs allow hard metals to be worked without causing discolouration.

- Technology VSM TOP SIZE: An active layer to improve cutting performance and reduce temperature.

- Multilayer vulcanized fibre support: Extreme resistance to deformations and tears.

- Secure attachment: 4 notch discs, suitable for angle grinders with a reliable fixing system.

-

Abrasive discs VSM ACTIROX AF799

- Geometrical ceramic seeds: Ensure more aggressive cutting and efficiency.

- Adapted to hard metals and stainless steel: Perfect for machining non-alloy steel, aluminum and stainless steel.

- Maximum material removal: Their abrasion performance is more than twice as high as conventional ceramic abrasive discs.

- Vulcanized multilayer support: Offers optimum resistance to deformation and tearing.

- Reliable attachment: Discs with 4 notches, for use with a rubber-ventilated top of Ø127 mm.

-

Abrasive discs ZF713 VSM

- Ultra-resistant Zirconium seeds: Ideal for low or medium pressure sanding.

- Self sharpening properties: Grains fragment to create new sharp edges and maintain optimal cutting performance.

- Thermal protection: Zirconium reduces heating, thus preserving the working surface.

- Robust vulcanized fibre support: Offers great resistance to shocks and deformation.

- Secure attachment: 4 notch discs for reliable fixing on angle grinders.

Benefits of Fibre Abrasive Discs VSM

- High performance material removal: The fibre abrasive discs VSM are designed to provide outstanding performance, even in the most demanding applications.

- Increased sustainability: The combination of robust supports and high-quality abrasive grains allows discs to last longer, reducing maintenance costs.

- Adaptability: Whether it is ceramics, of zirconium or advanced technologies VSM ACTIROX, these discs adapt to all types of materials and working conditions.

- Security guarantee: Certified by oSa®, the discs are designed to be used safely, even under high stresses.

- Clean working environment: The discs are designed to facilitate the removal of sanding dust and debris, thus ensuring cleaner work and better visibility in the work area.

Applications of Fibre Abrasive Discs VSM

- Hard metal grinding: The fibre abrasive discs VSM are perfect for grinding operations on the toughest metals such as stainless steel, aluminum, and alloys.

- Drafting: Ideal for removing edges and edges on metal parts.

- Surface finishing and preparation: These discs ensure clean and quality finishes on a wide range of materials.

- Industrial applications: Used in automotive, construction, metal, and many others for high precision results.

Why Choose Fibre Abrasive Discs VSM ?

The fibre abrasive discs VSM are designed to deliver optimal performance even in the most demanding applications. Their robustness, longevity and ability to adapt to a wide range of materials make it an essential choice for professionals looking for quality and efficiency. Whether you are in hard metal machining or in applications requiring precise and fast cutting, discs VSM are the ideal solution to meet your needs.