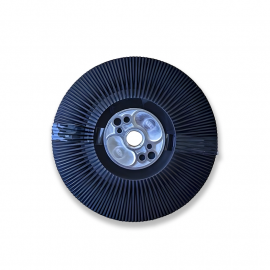

Abrasive Rings and Capuchons: The Reference for Precision Finishes

The abrasive rings and caps are distinguished by their versatility and efficiency in sanding and polishing. Whether professional in machining or demanding amateur, these products have been designed to meet the needs of the most diverse applications, ensuring consistent and high quality results.

Presentation and Benefits

Abrasive rings and caps are an innovative solution for surface processing. Their ingenious design makes it possible to achieve a homogeneous finish, while offering a prolonged wear of the abrasive tool. Some notable benefits include:

-

Optimal Performance:

The abrasive rings and caps ensure uniform distribution of the abrasive, allowing efficient cutting and polishing on different materials. -

Adaptability and versatility:

Available in various sizes and sizes, these products adapt to multiple applications, whether for working metals, plastics or other media. -

Sustainability and Longevity:

Designed with high quality materials, the abrasive rings and caps are wear-resistant, ensuring constant performance even when used intensively. -

Finish Impeccable:

Thanks to their specific design, these products offer a smooth and regular finish, essential for precision work.

Technical characteristics of the Abrasive Rings and Capuchons

Composition and Design

The abrasive rings and caps are characterised by:

-

Robust Materials:

Made from resistant supports, these products guarantee stability during sanding and polishing. -

High quality abrasives:

High performance abrasive coatings such as aluminium oxide or silicon carbide, they ensure precise and efficient cutting.

Format and Granulometry

-

Various formats:

Available in several sizes to fit different types of tools and working supports. -

Granulometry Adapted:

Offered in a wide range of grains, ranging from coarse to the quick elimination of imperfections, to the end for high precision finishes.

Applications of Abrasive Rings and Capuchons

Industrial processing

In the industrial sector, abrasive rings and caps are essential for:

-

Metal Polishing:

Offering a smooth surface without blush for preparation before final treatment (painting, anodization, etc.). -

The Finishing of Factoryed Parts:

Guaranteeing precise fit of mechanical parts and improvement of their aesthetics.

Maintenance and Repair Workshops

For maintenance workshops, these products allow:

-

BREAKDOWN AND POLISHING:

Ideal to eliminate irregularities and blush on machined parts. -

Surface Rehabilitation:

Used to restore a new appearance to equipment and machines.

Craft and DIY Applications

Even for tinkerers and small workshops, abrasive rings and caps offer:

-

A Great Facility for Use:

Adaptable on various tools, they allow a simple and efficient application. -

Professional Results:

Guaranteeing superior finishes on a variety of materials, from stone to wood to metal.

Use Tips to Optimize Your Results

Preparation and Selection

-

Choose the Good Grain:

Adapt the particle size of your abrasive rings and caps to the type of material and the desired result. -

Check Compatibility:

Make sure that the tool used is compatible with the format and shape of the abrasive rings and caps for optimal use.

Sanding and Polishing techniques

-

Uniform application:

Maintain a regular and controlled pressure to avoid premature wear of the abrasive and achieve a homogeneous finish. -

Regular Control:

Regularly inspect the state of the abrasive to ensure constant performance and avoid defects on the treated surface.

Conclusion

The abrasive rings and caps are a must-have solution for any professional or amateur looking for precise and high quality finishes. Their performance, durability and adaptability to various applications make it an essential tool for surface processing, whether in industrial machining, maintenance or even for DIY projects. By integrating these products into your arsenal, you guarantee professional results, increased efficiency and optimal satisfaction in all your sanding and polishing operations.

Optimize your finishing work today with our abrasive rings and caps and transform your projects into real success thanks to cutting-edge technology and proven quality.